When selecting the right lubricant for your machinery, understanding grease consistency is crucial. One of the most important indicators of grease consistency is its NLGI grade. In this post, we’ll explore what NLGI stands for, how it affects grease performance, and why it matters for your equipment.

What is NLGI?

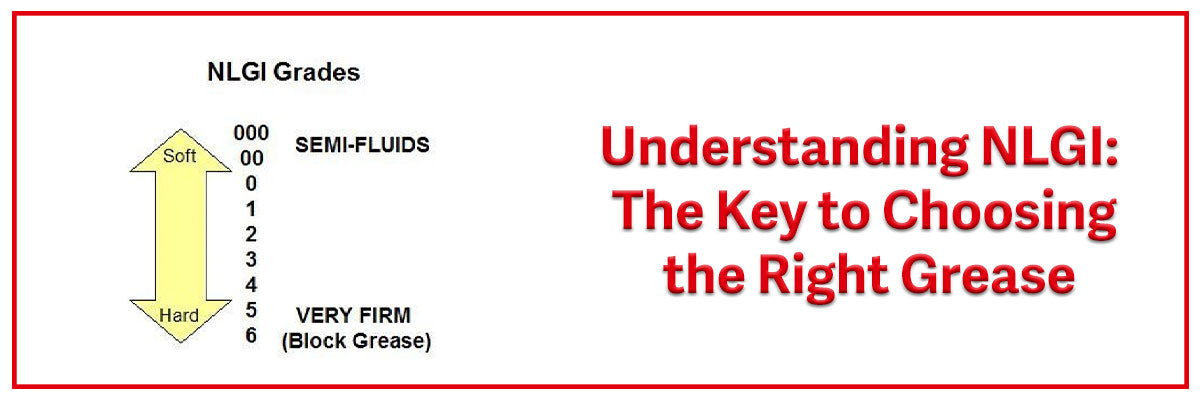

NLGI, or the National Lubricating Grease Institute, is an organization that sets industry standards for lubricating greases. The NLGI grade is a numerical scale that measures the consistency or thickness of grease, ranging from very fluid to very solid. This grade helps in selecting the appropriate grease for different applications and operating conditions.

How NLGI Grades Work?

NLGI grades are assigned based on the grease’s consistency, which determines its ability to stay in place and provide lubrication under various conditions. The scale ranges from 000 to 6:

- NLGI Grade 000: Very fluid, often used in centralized lubrication systems.

- NLGI Grade 00: Slightly thicker than 000, used in very low temperature conditions.

- NLGI Grade 0: Commonly used for applications requiring good pumpability and fluidity.

- NLGI Grade 1: Used in applications with moderate consistency requirements.

- NLGI Grade 2: The most commonly used grade, suitable for a wide range of applications.

- NLGI Grade 3: Thicker consistency, used in conditions where higher stability is required.

- NLGI Grade 4 to 6: Very thick, used for specialized applications where maximum stability is needed.

Why NLGI Grade Matters?

-

Consistency and Performance: The NLGI grade directly affects how well the grease performs. Lower grades (000-0) are more fluid and can flow more easily through lubrication systems, while higher grades (2-6) are thicker and provide greater stability. Choosing the right grade ensures that the grease can handle the specific demands of your application, whether it's high pressure, high temperature, or heavy loads.

-

Pumpability: Greases with lower NLGI grades (such as 0) are easier to pump through systems, making them ideal for automated lubrication systems or applications where grease needs to be delivered over long distances or through narrow passages.

-

Application Suitability: Different machinery and operating environments require different grease consistencies. For example, automotive and industrial machinery often use NLGI grade 2 grease for its versatility, while specialized applications may require a higher or lower grade to ensure proper lubrication and protection.

-

Operational Efficiency: Using the correct NLGI grade can improve the efficiency and lifespan of your equipment. Grease that is too thick might not flow properly, leading to inadequate lubrication, while grease that is too fluid might not stay in place, resulting in leakage or loss of lubrication.

Choosing the Right NLGI Grade

Selecting the right NLGI grade involves considering several factors, including:

- Operating Temperature: Ensure the grease can handle the temperature range of your application.

- Load Conditions: Higher pressure or heavy load applications may require a different grade.

- Environmental Conditions: Exposure to water, dust, or chemicals might influence your choice.

Understanding NLGI grades is essential for choosing the right grease for your equipment. By selecting the appropriate grade, you ensure optimal performance, protection, and efficiency of your machinery. Whether you need a fluid grease for easy pumpability or a thicker option for high stability, NLGI grades provide a standardized way to meet your lubrication needs.

For more information on selecting the right grease and to explore our range of products, visit BuySinopec’s grease collection. Our experts are here to help you find the perfect solution for your lubrication requirements.

Shop now and ensure your equipment runs smoothly with the right grease from BuySinopec!