What is hydraulic oil?

Hydraulic oil (also known as hydraulic fluid) can be synthetic or mineral based. It’s a non-compressible fluid that is used to transfer power within hydraulic machinery and equipment. As a hydraulic oil supplier, we deal with 99% of mineral-based hydraulic oils.

Although this useful fluid is commonly used in the transfer of power, hydraulic fluid can act as a sealant, coolant and lubricant within machinery and equipment.

The main difference between synthetic and mineral based hydraulic oil

The majority of oils which are produced are either mineral based or synthetic. Mineral based oils, such as mineral oil hydraulic fluids, are derived from crude oil whereas synthetic hydraulic oil is man-madein a lab.

Hydraulic Oil Product PRICE LIST

What is hydraulic oil used for?

The primary use of hydraulic oil is to transfer power within hydraulic systems. When a force is applied to the non-compressible hydraulic fluid, usually from a piston within a cylinder, the oil is pushed through the hydraulic system and ultimately produces a force on another part of the system. This results in a movement or action.

If you’re wondering whether hydraulic oil is compressible or not, the word non-compressible means that it cannot be compressed. All fluids are non-compressible whereas a gas is compressible. Liquids are compressible to some extent, although it is incredibly negligible and not considered for our guide.

Hydraulic fluids are used in many applications across the world. To give you an idea of the vast array of uses for hydraulic fluid, here are 10 examples of equipment and machinery which use hydraulic oil:

• Hydraulic Oil for a Forklift Truck – The hydraulic system within forklift trucks and stackers is important to help power the incredibly strong forks which need to lift some super-heavy goods.

• Hydraulic Oil for a Log Splitter – The ram mechanism on a hydraulic oil log splitter requires hydraulic fluid inside to give it that immense power which can split logs with ease. Log splitters are also known as wood splitters!

• Hydraulic Oil for Automotive Lifts – Car lifts (car jacks, automotive lifts, etc.) require hydraulic oil to aid their impressive power range! This type of machinery depends heavily on reliable hydraulic oil for safety as well as performance. Hydraulic oil for a car lift tends to have a higher viscosity grade for high pressure.

• Hydraulic Oil for Wright Standers – A wright stander is a stand on mower which is usually well-suited to cemeteries and other restrictive grassy areas. The hydraulic part of these machines requires hydraulic oil for power.

• Hydraulic Oil for Snow Ploughs (Snow Plows) – Hydraulic oil for a snow plough and ploughing equipment is essential in the powerful operation of the hydraulic lift, tilt and angle movements of the snow plough blade. The cold weather conditions associated with the use of a plough means that the hydraulic fluid used in a snow plough will be blended with antifreeze additives.

• Hydraulic Oil for Skid Steers (Skid-steer Loader and Skidsteer) – Skid steer hydraulic oil is as versatile as the machine it works with. For the many tasks this machine can competently complete, hydraulic oil plays a big role at all times.

• Hydraulic Oil for Aircraft (aviation) – Hydraulic oil for aviation control systems must be reliable. It is also used within aircraft hangar doors, aircraft jacks and aircraft controls.

• Hydraulic Oil for Air Tools – Air tools and air compressors require high-pressure hydraulic oil which contains anti-wear additives for protection.

• Hydraulic Oil for Tractors – Tractor hydraulic oil is necessary for the operation of hydraulic brakes and hydraulic systems on agricultural vehicles and machinery. For your hydraulic oil tractor supply, you may want to use a reputable manufacturer to ensure your expensive machinery and vehicles are well looked after and protected.

• Hydraulic Oil for Cruise Ships and the Marine Industry – If you’ve been lucky enough to go on a cruise ship then you’ll have felt the comforts out at sea. Hydraulic oil is used aboard many marine vessels for the stabilisers. The stabilisers reduce the amount of roll, which can affect the ship’s balance and cause you to experience unfriendly sea-motion sickness. This is just one of the many other applications on marine vessels which require hydraulic oil.

The contents of hydraulic oil

Hydraulic oil is made from a vairety of different ingredients. These ingredients can often be mixed depending on the type of oil you require.

Generally speaking, hydraulic oil is made up of:

• Mineral oil

• Esters

• Glycol

• Silicone

• Ethers

• Esters

• Some other chemicals which are hard to pronounce!

For the varied applications of hydraulic fluid, blenders will mix it with various additives to give it different properties.

Hydraulic oil additives

Depending on its use, there will be extra additives which help it perform under different conditions. Different hydraulic oil additives include:

• Anti-wear – helps prolong the life of equipment and machinery

• Cold Flow – additives that enable useage in extreme cold weather conditions

• Anti-foaming – An anti-foaming agent for hydraulic oil reduces foaming within the fluid which can be caused by detergents. This foaming can reduce the lubricating quality of the product, thus causing damage.

• Anti-oxidant – Allows for longer periods of use without an oil change while also reducing sludge deposits.

• Anti-rust – Forms a protective coating which reduces the risk of rust damage from oxygen contact.

These additives are used on their own and together in different blends which are created for different purposes. Hydraulic oil properties can be altered depending on which additives are used, but the typical characteristics tend to be a high viscosity index and be incompressible.

Below is a list of common uses for hydraulic oil and the type of additive/s which may be added to the oil to help it perform at its optimum level.

Hydraulic oil for winter

Hydraulic power is required in some of the coldest places on earth. In these cases, anti-freeze additives are used to prevent the fluid from freezing up or waxing. Low-temperature hydraulic oil is commonly used as a name for fluid which needs to be used in icy conditions.

Hydraulic oil for high heat applications

Under high heat, oil becomes less viscous and flows easier, which means that it can leak or lose its required properties. Additives are used to retain viscosity for fluids used in applications involving exposure to higher temperatures.

Hydraulic oil for heavy duty

Heavy-duty hydraulic oil is necessary for high-pressure environments where the fluid needs to be able to cope with large amounts of stress. The hydraulic oil additives used here will typically contain anti-wear properties. Anti-wear hydraulic oil is one of the most common blends used in industry and construction.

Environmentally friendly hydraulic oil

Biodegradable hydraulic oil is used in applications where an oil spill or leak could potentially contaminate the environment. The typical base oil for biodegradable versions of hydraulic oil include rapeseed oil and some other vegetable oils.

Hydraulic oil in more detail

Hydraulic oil classification

The classifications of hydraulic oil are a subgroup of different fluids with varying performance levels. Below is a list of common hydraulic oil classifications and their respective descriptions:

• HL – Refined mineral oils with anti-oxidation and anti-rust properties

• HM – HL with improved anti-wear properties

• HR – HL oils with VI improvers

For a detailed list contact your supplier or click this link.

Hydraulic oil ratings

When an additive company sells an additive pack, they will work alongside a particular manufacturer to create a product which works perfectly with that manufacturer’s application. This will be traceable by a hydraulic oil supplier who has used the additive in the fluid. Hydraulic oil ratings or approvals are stipulated by many end users of oil to ensure they’re using the correct fluid for their equipment.

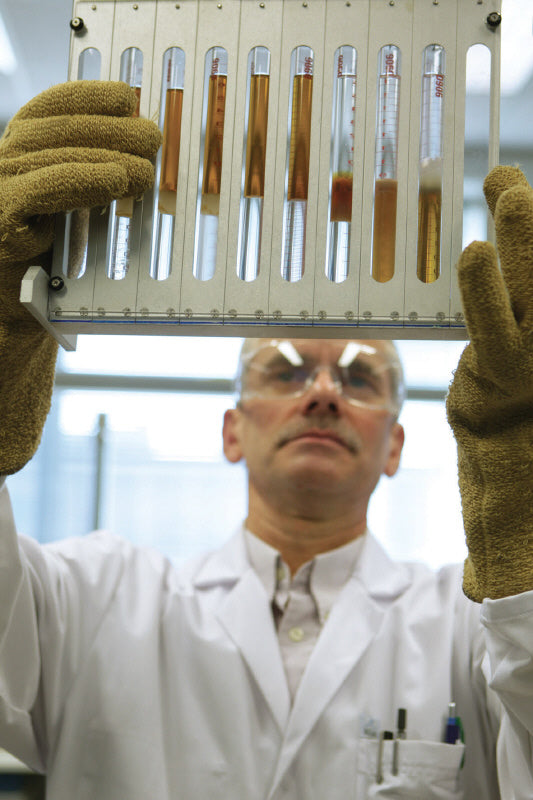

Hydraulic oil analysis

Commonly known as condition monitoring, a hydraulic oil analysis service is used by people who want the most out of their oil before they have to change it in their hydraulic application.

They send a sample of their hydraulic oil to a lab which analyses the sample and reports back with details as to whether it’s good to use further or if it needs to be changed. This gives the end user reassurance that it is still usable and no damage can be done to expensive equipment due to dirty or worn oil.

Why is hydraulic oil analysis important?

The importance of oil analysis should be high on anybody’s list. Below is a list of just a few reasons why it shouldn’t be ignored and how it pays for itself many times over:

• Reduces the cost involved in replacing the oil prematurely.

• Minimises damage to your machinery by identifying issues early.

• Has the potential to enhance the life and performance of machinery.

• Reduces the risk of damage to machinery and products.

• Reduces the risk of injury to people and further costs in claims and damages.

Hydraulic oil temperature range

Depending on the application of hydraulic fluid, it may be subject to cold or hot temperatures. In some cases, hydraulic oil can be subjected to both hot and cold temperatures which can render the oil useless if it hasn’t been blended with the right additives.

Hydraulic fluids have temperature stability which means they’ll retain their properties within a particular temperature range. Anything above or below this will negatively affect the temperature stability and cause the fluid to either wax and freeze under cold conditions or lose viscosity and potentially leak under hotter temperatures. High-heat can cause rapid deterioration of hydraulic oil.

Viscosity of hydraulic oil vs temperature

The viscosity of hydraulic oil and temperature is closely linked. As temperature increases, the viscosity of oil will decrease – a bit like when you put cooking oil in a cold pan it moves slowly but when the pan heats up the oil moves around very quickly and with ease. As the temperature drops hydraulic oil will become more viscous.

Blenders are always trying to make hydraulic oil operate effectively over a wider range of temperatures. This means they’ll go down to low temperatures and still work as effectively as the temperature increases.

Hydraulic oil viscosity index

To measure the change in viscosity of hydraulic oil when the temperature changes, we use the oil viscosity index (VI). If a hydraulic oil has a low viscosity index, a change in temperature will alter the viscosity more than if it has a high viscosity index.

Hydraulic oil with a high VI will usually be required in an application which is subjected to a greater range of ambient and/or operating temperatures.

A straight paraffinic mineral base oil will typically produce a fluid with a low viscosity index, whereas a paraffinic mineral base with viscosity improvers will produce a fluid with a high viscosity index.

The SAE (Society of Automotive Engineers) created a classification table (VI Scale) to show low to high viscosity levels depending on temperature °C. Originally the scale only went up to 100°C but with advances in hydraulic oil blends, the scale now goes above this number!

Viscosity Index Classification

0-35°C Low

35-80°C Medium

80-110°C High

110°C and greater Very High

Hydraulic oil viscosity explained

The viscosity of hydraulic oil is the measurement of its resistance to flow. This means the fluid will resist compression at different rates depending on its viscosity and take longer to pass through an orifice as the viscosity increases. Hydraulic fluid with high viscosity will be thicker and harder to compress and move as opposed to low viscosity hydraulic oil which will be runnier and pass through easier.

The viscosity of hydraulic fluid is measured in Centistokes (cSt) and usually at temperatures of 40°C and 100°C. The value will always have the temperature next to it as without this the value will be meaningless. A fluids viscosity is measured in a lab using a viscometer as pictured below!

Hydraulic oil viscosity is important for each different application.

The wrong viscosity could cause damage to equipment or have poor results in function.

Hydraulic oil viscosity conversion chart

Please note:

This chart should be read across horizontally. It assumes 96 VI single grade oils. The equivalence is in terms of viscosity at 40°C only. Viscosity limits are just an approximate; for precise data then you should consult your supplier, ISO, AGMA and SAE specifications. W grades are represented only in terms of approximate 40°C viscosity. For low-temperature limits, consult SAE specifications.

Hydraulic oil grades

ISO VG – ISO Grade (International Standards Organisation) – the higher the VG number the more viscous the fluid is. This tells you which hydraulic oil is thicker. This is sometimes referred to as the hydraulic oil weight. Grades with a W next to them indicate the weight (Unlike automobile engine oil which refers to winter oil).

AGMA Grade – American Gear Manufacturers Association – Leaders in the standards of gear oils.

SAE – Society of Automotive Engineers

In the UK, ISO VG is used mainly for grading hydraulic oil. Below is a list of common hydraulic oil ISO grades and a general guide to their applications:

Hydraulic oil flash point

The hydraulic oil flash point is the lowest temperature at which enough vapours are released from the fluid which can be combustible.