Choosing the correct weight of oil is paramount when selecting a lubricant for industrial applications. To assist in making an informed decision, it's essential to understand the different classifications and how they relate to the viscosity or thickness of the oil. Here, we delve into the three primary acronyms used in the industry: ISO VG, AGMA, and SAE, and explain how they can guide you in selecting the most appropriate lubricant for your machinery.

ISO VG: The Standard for Industrial Lubricants

ISO VG, or International Standards Organization Viscosity Grade, is the cornerstone for classifying the viscosity of industrial lubricants. Unlike automotive oils, ISO VG is almost exclusively used for industrial applications and provides a clear, numerical value based on the oil’s viscosity measured at 40°C (104°F). This system allows for precise matching of lubricant properties to the specific requirements of various types of machinery and equipment.

ISO VG Grades

ISO VG standards measure the viscosity of industrial lubricants at 40°C (104°F), providing a range that helps users determine the best oil for their specific application. Here’s a breakdown of some common ISO VG grades:

- ISO VG 22 – This is a low-viscosity grade often used in devices requiring a thinner oil for minimal resistance and quick start-up at lower temperatures.

- ISO VG 32 – Suitable for general hydraulic systems, air compressors, and turbine oils, providing excellent fluidity and hydraulic stability.

- ISO VG 46 – Ideal for systems with variable temperatures, this grade offers a balance between thin fluidity and sufficient protective film at higher temperatures.

- ISO VG 68 – Commonly used in gear oils, hydraulic systems, and compressors where high-load carrying stability is essential.

- ISO VG 100 – Perfect for high-stress applications like gearboxes, and where high temperatures are common, this grade maintains a good film thickness to protect against wear.

For a closer look at specific examples within each category, please click on the images below:

AGMA: Specialized for Gears

The American Gear Manufacturers Association (AGMA) standard is specifically designed for gear lubricants. AGMA numbers correlate closely with ISO VG grades but are tailored to address the unique demands of gear systems, such as load-bearing capabilities and meshing efficiency. Understanding AGMA ratings is crucial for maintaining the longevity and performance of gear systems.

AGMA Classification Overview:

- AGMA Numbering: The AGMA classification uses numbers such as AGMA 1, AGMA 2, AGMA 3, etc., to indicate the viscosity grade of the gear oil. These numbers increase as the viscosity of the oil increases.

- Viscosity Matching: Each AGMA grade matches a specific viscosity range measured in centistokes (cSt) at 40°C, similar to the ISO VG system. This makes it easier for users to select the correct lubricant for their gear system based on operational requirements.

- Specific Applications: The AGMA standards not only specify the viscosity but also include recommendations for other properties relevant to gear lubricants, such as EP (Extreme Pressure) characteristics, which are crucial for high-load applications.

For a closer look at specific examples within each category, please click on the images below:

SAE: From Autos to Industrial Use

While the Society of Automotive Engineers (SAE) grading is more commonly associated with automotive lubricants, it also finds relevance in industrial settings, particularly for gear oils and heavy-duty hydraulic systems. SAE grades are determined based on viscosity measurements at both high and low temperatures, which makes them useful for applications subject to variable operational climates.

SAE Grades

Unlike ISO VG, which is measured at 40°C, SAE grades are primarily used for automotive lubricants and are measured at both cold (for W grades) and high temperatures:

- SAE 10W – A winter-grade oil that ensures good fluidity and pumpability at low temperatures.

- SAE 15W – Similar to SAE 10W but with slightly higher viscosity for colder climates.

- SAE 20 – Suitable for moderate climate use, providing adequate lubrication without excessive thickness.

- SAE 30 – Often found in older engines and equipment, this single-grade oil is ideal for consistent temperature use.

- SAE 50 – This high-viscosity oil is best for hot climates or severe high-load conditions where a thicker oil film is necessary for protection.

Comparing ISO VG, AGMA, and SAE

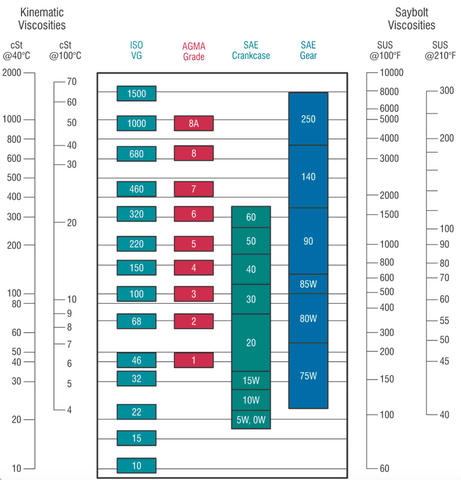

Though these classifications differ, they are interrelated and can be approximately translated across systems to simplify the selection process. For example, AGMA 2 oil is roughly equivalent to SAE 80 Gear Oil and ISO VG 68, offering a baseline to compare products across different standards. However, it's crucial to consult your equipment's manufacturer documentation to choose the lubricant that meets the precise specifications required.

Cross-Reference and Comparisons

- AGMA to ISO VG: There is a direct correlation between AGMA and ISO VG numbers for many lubricants. For instance, AGMA 2 often matches ISO VG 68, and AGMA 4 matches ISO VG 150.

- AGMA to SAE (Gear Oils): AGMA lubricants sometimes cross-reference to SAE gear oil grades. For example, AGMA 5 might correspond to SAE 80W-90 gear oil based on viscosity.

-

ISO VG to SAE (Hydraulic and Motor Oils): While ISO VG numbers can be compared directly in terms of viscosity at 40°C, SAE numbers require consideration at both low and high temperatures. However, there are approximate equivalences for specific applications (e.g., ISO VG 32 might be similar in viscosity to SAE 10W at operating temperature).

Importance of Correct Lubricant Selection

Understanding the nuances of ISO VG, AGMA, and SAE classifications is essential for any professional managing industrial machinery. By using these standards to guide your lubricant selection, you can enhance equipment performance and reliability. Remember, the key to optimal lubrication lies not just in choosing the right weight but also in selecting a product that aligns with the specific needs of your application.

Selecting the right lubricant weight is not just about ensuring smooth operation; it also impacts the maintenance costs, energy efficiency, and lifespan of your equipment. Inaccurate lubricant selection can lead to increased wear and tear, higher energy consumption, and even catastrophic equipment failures.

If you need to select the appropriate lubricant that matches your needs, please visit our website for further information.

www.buysinopec.com