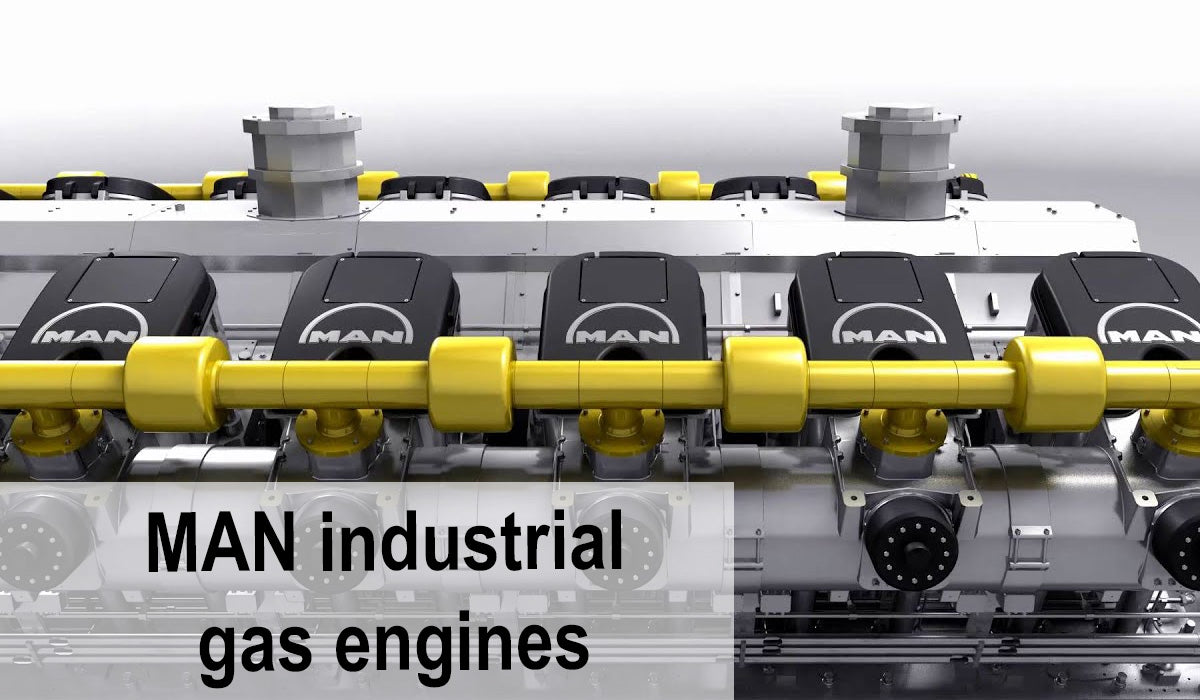

MAN industrial gas engines are renowned for their reliability, efficiency, and adaptability across various sectors, from power generation to manufacturing. These engines are designed to operate on natural gas, biogas, and other gaseous fuels, making them a versatile choice for many industries. Here, we delve into the core features, benefits, and essential maintenance tips for MAN industrial gas engines.

1. Versatile Fuel Options for Maximum Efficiency

MAN gas engines are compatible with a wide range of fuel types, including natural gas, biogas, landfill gas, and synthetic gas. This flexibility allows industries to optimize costs and reduce environmental impact by utilizing locally available and renewable energy sources.

Key Benefits:

-

Reduced carbon footprint.

-

Lower operational costs.

-

Enhanced energy efficiency.

2. Advanced Combustion Technology

Equipped with state-of-the-art combustion systems, MAN gas engines ensure optimal fuel utilization, resulting in higher efficiency and lower emissions. The engines are designed to meet stringent environmental regulations without compromising performance.

3. Durability and Longevity

These engines are built with high-quality materials and precision engineering, offering exceptional durability and extended operational life. Regular maintenance and the use of high-quality engine oils can significantly prolong their lifespan.

Recommended Maintenance Tip:

Use oils that provide excellent thermal stability and deposit control to maintain engine performance.

4. Proactive Maintenance Practices

To maximize the performance and longevity of MAN industrial gas engines, implementing a proactive maintenance routine is essential. Regular inspections, oil analysis, and component checks help in early detection of potential issues.

Essential Maintenance Steps:

-

Regularly check and replace air filters.

-

Monitor and analyze engine oil.

-

Inspect ignition systems and spark plugs.

5. The Role of Engine Oil in MAN Gas Engines

Choosing the right engine oil plays a crucial role in maintaining engine performance and efficiency. Oils with the appropriate ash content and anti-wear additives help reduce deposits, prevent corrosion, and ensure smooth engine operation.

Suggested Product:

Natural Gas SAE 40 Stationary Engine Oil

-

Optimized for stationary gas engines.

-

Superior thermal and oxidative stability.

-

Low ash content to minimize deposit formation.

Free shipping on 2+ drums in CA, TX, FL, and NJ.

By understanding the operational needs and maintenance requirements of MAN industrial gas engines, industries can achieve consistent performance, enhanced efficiency, and reduced operational costs. Regular maintenance, coupled with the use of high-quality oils, ensures these engines continue to deliver reliable power for years to come.